MENU

Production capacity

Advanced injection molding equipment

The company has 11 sets of advanced injection molding equipment, with injection molding tonnage ranging from 90 tons to 650 tons, injection molding gram weight ranging from 50g to 3000g, and 30 years of processing experience in various difficult materials such as PC,PMMA, transparent ABS, modified PA, etc. Injection molding whole network monitoring, visual management.

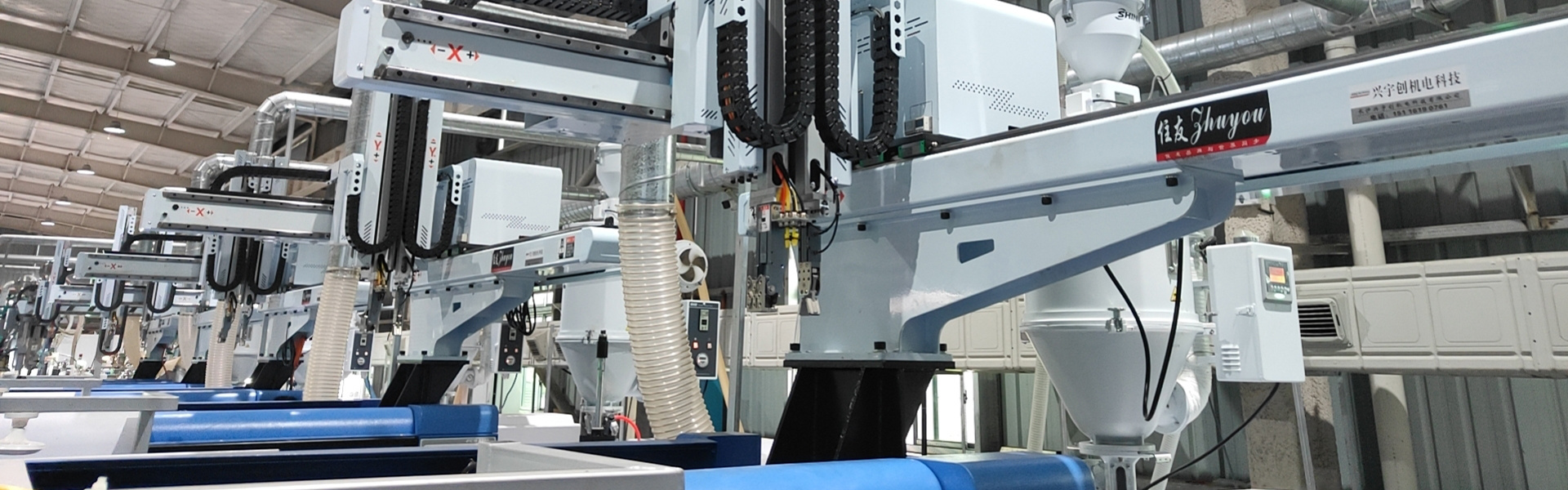

Branded auxiliary machine

The injection workshop manipulator, intelligent drying material, feeding system, automatic assembly line and other auxiliary machines all adopt Sumitomo brand. All organic stations are equipped with a masterbatch machine and a colorimeter to monitor the color of the product.

Branded auxiliary machine

The injection workshop manipulator, intelligent drying material, feeding system, automatic assembly line and other auxiliary machines all adopt Sumitomo brand. All organic stations are equipped with a masterbatch machine and a colorimeter to monitor the color of the product.

Intelligent Pipeline

There are two intelligent assembly lines in the assembly workshop, from laser intelligent marking to product sealing and packaging. The daily packaging of intelligent pet drinking fountains can reach 4000 units. The production of water dispenser filter adopts advanced hot melt technology and automatic canning, automatic packaging process.

toll-free hotline

Address

No. 48, Lufeng Road, High-tech Development Zone, Changsha City, Hunan Province China

Taobao Store

Jingdong Store

This site supports IPv4、IPv6.

Powered by www.300.cn ChangSha | SEO | Customer back office

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.